Research Plan/Project Summary -Ziyang Wang

1. Background (Rationale)

The inspection and maintenance of large steel structures, such as high-voltage transmission towers and steel beam bridges, are crucial for ensuring their safety and longterm durability. However, traditional manual inspection methods are inefficient and pose safety risks, especially when working at heights or in hazardous environments. To address these challenges, this project aims to develop a robotic system for inspecting steel structures.

The robot is designed to autonomously crawl on steel surfaces using electromagnetic adhesion and a rack-and-pinion drive system that enables stable forward, backward, and turning maneuvers. The robot is equipped with a LiDAR sensor for detecting obstacles and a camera coupled with the YOLO algorithm for detecting corrosion on steel surfaces. A ROS (Robot Operating System) framework coordinates and manages communication between the robot’s sensors and actuators, enabling autonomous obstacle avoidance and inspection.

The goal of this project is to leverage automation technology to improve the efficiency and safety of steel structure inspections, reduce the need for manual intervention, and enhance inspection accuracy. This will provide a safe, cost-effective, and efficient solution for steel structure maintenance in industries such as power transmission and transportation.

2. Research Questions, Hypotheses, and Objectives

Research Questions:

- How can a robot be designed to stably traverse the surfaces of high-voltage transmission towers or steel beam bridges while detecting obstacles and identifying corrosion areas?

- How can the robot automate the detection of corrosion on steel surfaces, and how can ROS coordinate the operation of multiple sensors and actuators?

Hypotheses:

- Using electromagnetic adhesion, the robot can stably traverse steel surfaces.

- LiDAR can effectively detect obstacles, and ROS can coordinate obstacleavoidance maneuvers.

- The camera, combined with YOLO, can identify corrosion areas on steel surfaces.

- ROS can efficiently manage communication between the robot’s components (motors, electromagnets, actuators, servos, LiDAR, and camera) to ensure autonomous inspection and motion control.

Engineering Objectives:

- Design and build a robot capable of autonomously traversing the surfaces of highvoltage transmission towers or steel beam bridges, using a rack-and-pinion system for precise forward, backward, and turning movements.

- Integrate a LiDAR sensor for obstacle detection and a camera for corrosion detection, with ROS managing sensor data integration and control.

- Complete system debugging, enabling the robot to autonomously avoid obstacles, inspect steel surfaces, and execute precise turns using servos.

Expected Outcomes:

- The robot will be able to stably adhere to steel surfaces, using the rack-and-pinion mechanism and servo motors to move forward, backward, and turn smoothly.

- The LiDAR sensor will successfully detect obstacles ahead, and ROS will coordinate obstacle avoidance.

- The camera, coupled with the YOLO algorithm, will identify corrosion areas and record their locations.

- ROS will efficiently manage the robot’s movement and sensor data communication, ensuring global control of the system.

3. Detailed Description

Materials List:

- Arduino Control Board: Controls the robot’s actuators, electromagnets, encoders, and servos.

- NUC Mini-PC: Processes data from the LiDAR and camera, runs the YOLO image recognition algorithm, and controls the system via ROS.

- Actuators: Lift and lower the robot’s legs.

- Electromagnets: Attach the robot to the steel beam, providing sufficient adhesion force.

- Encoder Motors: Drive the rack-and-pinion system, enabling the robot to move forward and backward.

- Servos: Control the robot’s steering by adjusting the angle between the front and rear legs, allowing the robot to change direction.

- Rack-and-Pinion System: Couples the robot’s legs to the steel beam, driving movement through gear engagement.

- LiDAR Sensor: Detects obstacles in front of the robot and provides distance information.

- Camera: Detects corrosion on steel surfaces through image analysis.

Procedures:

- Robot Structure and Control:

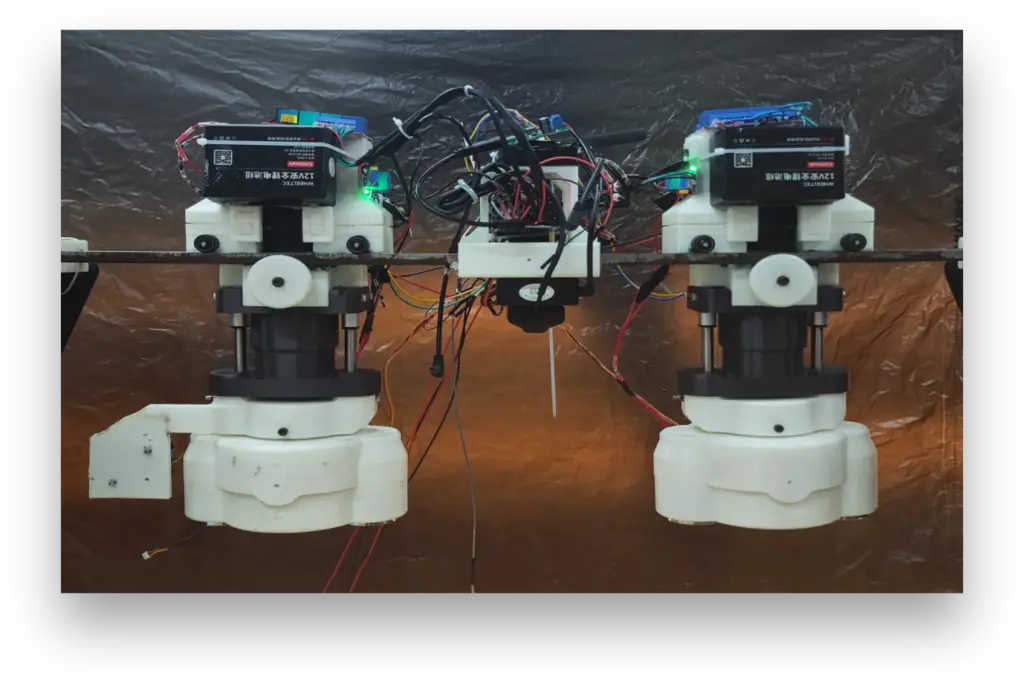

- The robot consists of two pairs of legs (front and rear), each with upper and lower sections.

- Leg Structure: The upper part is controlled by two actuators, which lift and lower the lower section. The lower section has two electromagnets that attach to the steel surface, providing adhesion.

- Drive System: The robot uses a rack-and-pinion system. The rack is mounted on the steel beam, and the robot’s encoder motor drives the pinion gear along the rack, enabling precise movement. This ensures stable traversal of the steel beam. o Movement Mechanism:

- The rear leg’s electromagnets disengage, and actuators lift the front leg.

- The encoder motor drives the pinion along the rack, moving the rear leg forward.

- The rear leg is lowered and re-engaged with the steel surface, and the front leg follows the same movement pattern.

- Servos control the angle between the front and rear legs, allowing the robot to turn.

- Once both legs are in the desired position, the motors rotate counterclockwise, moving the robot forward along the rack.

- Servo Steering Control:

- Servo Function: Servos adjust the angle between the front and rear legs, enabling the robot to change direction as it moves along the steel surface, helping it avoid obstacles or adjust its path.

- LiDAR Obstacle Detection and Avoidance:

- LiDAR Function: LiDAR operates independently, continuously detecting obstacles in front of the robot and measuring the distance to them.

- ROS Integration: LiDAR data is transmitted to the NUC via ROS, which relays obstacle information to the Arduino controller. If the detected

distance falls below the safety threshold, ROS will instruct the robot to lift to a higher altitude or adjust the servo angle to ensure it crosses or avoids the obstacle.

- Camera and YOLO Corrosion Detection:

- Camera Function: The camera works independently of the LiDAR, capturing real-time images of the steel surface.

- YOLO Algorithm: The images captured by the camera are processed through the YOLO algorithm to detect corrosion areas in the image.

- ROS Integration: Camera data is transmitted to the NUC via ROS, which coordinates YOLO image processing and records the location of detected corrosion areas. The results are fed back to the ROS system for subsequent analysis or report generation.

- ROS Functionality:

- Communication Management: ROS coordinates communication between different sensors (LiDAR, camera) and actuators (motors, electromagnets, actuators, servos).

- Data Processing: ROS consolidates LiDAR obstacle detection data, camera image data, and feedback from the robot’s movement, making real-time decisions such as obstacle avoidance, turning, and path planning.

- Control Logic: ROS executes the global control logic, such as stopping or turning the robot when an obstacle is detected, recording the location of corrosion, and sending alerts.

4. Advantages

- Unmanned Operation, High Safety:

- Traditional steel structure inspections often require human operators to work at heights, posing significant safety risks, such as falls or electric shocks. With this robotic system, manual inspections are fully replaced, eliminating the risks associated with working at height and greatly improving the safety of the inspection process. Unmanned operation reduces dependence on skilled personnel and minimizes exposure to hazardous environments, significantly lowering the risk of accidents.

- Flexible Mobility, Adaptability to Complex Environments:

- Unlike most wall-climbing robots available on the market, this project’s robot features flexible steering control. By adjusting the angle between the front and rear legs via servos, the robot can move in multiple directions and turn. This enables it to not only crawl in a straight line but also make agile turns on complex steel surfaces, cross obstacles, and adapt to various structures, such as angular steel towers and steel beam bridges. This flexibility allows the robot to perform inspections efficiently in a wide range of scenarios.

- All-Weather Operation and Environmental Adaptability:

- The robot is designed with dust-proof and waterproof features to withstand harsh working environments, such as high altitudes, strong winds, and rain. Unlike drones or other inspection tools, this robot is not dependent on weather conditions and can operate stably in harsh environments, making it particularly suitable for inspecting steel structures in high wind or high humidity conditions. For instance, in high-altitude areas where drones may struggle to fly due to strong winds, this robot can easily handle such challenges, ensuring continuous inspection operations.

5. Risks and Safety

- Use of Electromagnets: The electromagnets generate strong adhesive forces during operation, so operators must avoid placing their fingers in the adhesion zone. During use, it is critical to ensure that the magnets provide sufficient force to support the robot’s weight, preventing accidental detachment.

- High-Altitude Operational Risks: The robot operates on steel beams or transmission towers at high altitudes, so structural integrity must be maintained to prevent the robot from falling due to power failure or malfunction. Emergency measures should be incorporated into the design to ensure that the robot stops and remains adhered to the surface in case of an emergency.

- Electrical Equipment Risks: The robot’s electrical components may overheat or short-circuit during extended operation. To mitigate such risks, all motors and controllers will be equipped with overload protection circuits, and a cooling system will be included in the design.

- Protection of LiDAR and Camera: The LiDAR and camera are precision instruments that must be protected from external impacts or harsh environments (e.g., dust, rain). The housing should be designed with waterproof and dustproof capabilities, with additional protection for sensor areas.

6. Data Analysis

- Movement Data Analysis:

- Encoder motor feedback will record the distance, speed, and stride of each leg movement, analyzing the robot’s performance on various slopes and surface conditions.

- Obstacle Detection and Avoidance Analysis:

- Distance data from the LiDAR will be used to analyze the robot’s obstacle avoidance performance under different conditions.

- Corrosion Detection Data Analysis:

- Images captured by the camera will be compared with YOLO-identified corrosion areas to evaluate detection accuracy, false positive rates, and false negative rates.

- ROS will log each corrosion detection result and generate analysis reports to optimize YOLO’s recognition performance.

7. BIBLIOGRAPHY

- Peng, X., Zhang, Y., & Liu, T. (2019). A climbing robot for steel bridge inspection. Industrial Robot: the international journal of robotics research and application, 46(6), 718-729.

- Li, J., Bi, S., & Lin, M. (2020). A review of recent research on wall-climbing robots for inspection. Robotics and Autonomous Systems, 133, 103630.

- Cha, Y. J., Choi, W., & Büyüköztürk, O. (2017). Deep learning‐based crack damage detection using convolutional neural networks. Computer‐Aided Civil and Infrastructure Engineering, 32(5), 361-378.

- Wang, X., & Zhang, H. (2019). Design and implementation of a bridge inspection robot. IOP Conference Series: Materials Science and Engineering, 569(3), 032069.

- Redmon, J., Divvala, S., Girshick, R., & Farhadi, A. (2016). You only look once: Unified, real-time object detection. In Proceedings of the IEEE conference on computer vision and pattern recognition (pp. 779-788).

- Quigley, M., Conley, K., Gerkey, B., Faust, J., Foote, T., Leibs, J., … & Ng, A. Y. (2009). ROS: an open-source Robot Operating System. In ICRA workshop on open source software (Vol. 3, No. 3.2, p. 5).

- Aracil, R., Saltarén, R. J., Sabater, J. M., & Alacid, J. M. A. (2006). Robots paralelos: Máquinas con un pasado para una robótica del futuro. Revista iberoamericana de automática e informática industrial, 3(1), 16-28.

- Sahbel, A., Abbas, O., & Sattar, T. P. (2020). System design and implementation of wall climbing robot for wind turbine blade inspection. In 2020 2nd International Conference on Sustainable Engineering Techniques (ICSET) (pp. 38-43). IEEE.

- Zhu, J., Sun, K., Jia, S., Li, J., Hou, X., Pan, L., & Ma, Q. (2019). Junction detection and classification in steel bridge orthotropic decks using deep learning. Automation in Construction, 107, 102968.

[10]Zheng, H., Zhu, W., & Lu, H. (2019). Real-time weld defect detection in steel pipe using deep learning. Journal of Physics: Conference Series, 1213(5), 052032.